Wherever you find a loaded pallet, you’re likely to find a pallet truck close by to move it. Pallet trucks, or pallet jacks as they’re widely known, are used in nearly every industrial, warehouse, wholesale and even big-box retail facility across the nation. Countless American workers use these indispensable pieces of material handling equipment. Many pallet truck operators are very familiar and proficient with moving large loads with their pallet trucks, yet accidents still happen.

Almost all pallet truck accidents are preventable. Although the contributing reasons for pallet jack mishaps vary, the root cause for most pallet truck accidents is human error. Unfortunately, pallet jack safety is something that’s often taken for granted in some businesses, and it’s here where the majority of incidents causing personal injury or property damage are highest. They don’t have to be.

If companies rigidly follow pallet jack safety procedures, it significantly reduces the odds of having an accident. Initiating a hand pallet truck safety program in your facility might sound excessively cautious, but an ounce of prevention is always worth a pound of cure. That’s especially true when it comes to manual pallet truck safety.

Jump To Sections:

You might think pallet truck accidents are rare, infrequent or minor in nature, but that’s not what statistics show. Material handling is always risky, and a warehouse environment presents a high percentage of industrial accidents and injuries. Many incidents involve the improper or careless use of pallet trucks that resulted in serious injuries. The majority of pallet truck-related injuries are back strains. However, foot and hand crushes also often happen with improper pallet jack use.

The Occupational Safety and Health Administration (OSHA) dictates clear and strict regulations governing pallet truck use. That includes both manual pallet jacks and electrically-powered units. OSHA statistics show that

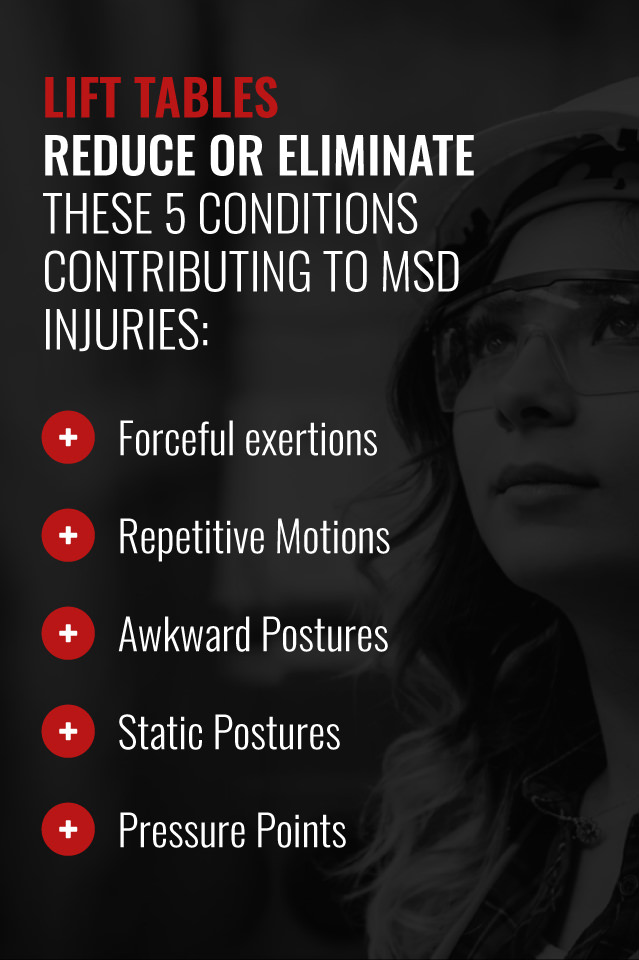

Back strains are far too common in American workplaces. The U.S. Bureau of Labor Statistics published that over one million workers suffer back strain injuries annually. Back strains comprise one in every five workplace injuries and amount to 25 percent of workers’ compensation claims. This costs billions of dollars to the United States economy, and some of it could be saved by paying attention to basic safety procedures when operating pallet trucks.

Preventing pallet truck injuries requires attention and dedication on both the employee’s and employer’s part. Two of the biggest contributors to pallet jack accident are the lack of proper training and simple complacency. Both can be overcome with implementing pallet truck safety protocols and ensuring workers are knowledgeable and compliant in operation.

To help improve your team’s performance in the warehouse or on the loading dock, it’s best to build an education program. That starts with outlining the basics of safely handling all forms of pallet jacks as well as reviewing the safety principles of loading pallets themselves. Pallet truck safety goes hand-in-hand with pallet safety as the two components combine to present potentially hazardous situations. Here are some pallet jack safety tips, starting with manually operated pallet movers.

It is vital to use proper best practices when operating pallet trucks, because the safety of your employees depends on it. Manual pallet trucks are a very simple, cost-effective solution, but require greater manual force to operate. On the other hand, electric pallet trucks do the heavy lifting for you, making your job easier and more feasible when working on loads with heavy weights. Each type of pallet truck has its own safety concerns due to the different manner of use. Read on to learn more about safe usage of manual and electric pallet trucks.

There are many different models of pallet trucks on the market, and they’re supplied by a variety of manufacturers. Although this assortment of material handling equipment all has different features like load capacities and safety devices, pallet trucks can be divided into two separate categories — manual pallet jacks and powered pallet trucks. These two groups may serve the same general purpose of transferring pallets from one location to another, but OSHA views them as being different when it comes to operator safety training.

Under OSHA rules, manual pallet jacks can be used by anyone without being trained in safe and proper use. This official view changes as soon as a pallet truck is powered by anything besides human muscle. Electrically-powered pallet jacks comprise the vast majority of powered trucks, followed by a small number of specialty outdoor pallet jacks propelled by gasoline or propane internal combustion engines. Actual forklifts are not considered pallet trucks by OSHA. Forklifts are specifically identified and require a more advanced form of training.

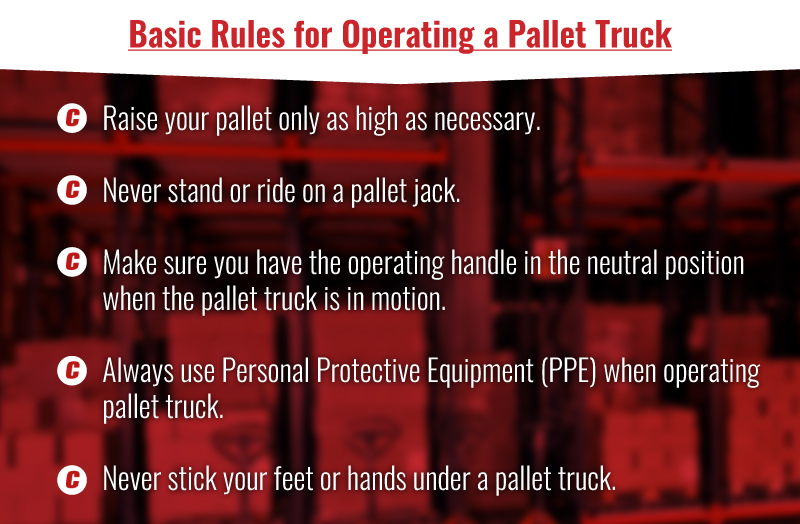

However, just because manual pallet jacks do not require OSHA formal training and documentation doesn’t mean there aren’t safety risks associated with even the lightest capacity trucks. The same safety principles apply whether workers are operating a 3,000-pound capacity jack or a huge model capable of lifting over 10,000 lbs. People can be injured just as severely, and property can also be damaged by improper operation of any pallet jack. Let’s look at some tips on safely handling manual pallet trucks:

Here are some additional safety tips before you or your employees begin operating a manual pallet truck:

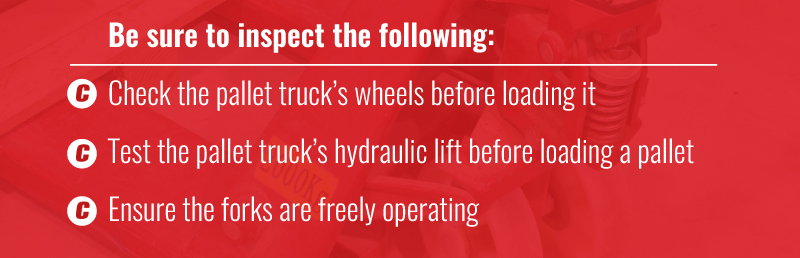

The pallet trucks components all work together for it operate, and when a part of it, like the wheels, aren’t up to the standards they should be, a pallet truck can be rendered unsafe — and inefficient. Be sure to inspect following:

It’s difficult to operate a machine safely if you aren’t familiar with its operating capacity. It’s also ideal to make sure you’re aware of any potential hazards along your route of travel with the machine:

A little bit of common sense is involved to ensure you or your employees stay safe during pallet jack operation. Take a look:

Slowly start a pallet truck into motion. Never jerk or whip a jack by the handle as this will place a sudden strain and shock on your muscular-skeletal system. This is a leading cause of injury from pallet jack operation and is easily avoided by putting gradual force on the truck’s handle. Here are a few other tips to help ensure you avoid injury during routine operations:

You’ll get different opinions from two different schools of thought about whether it’s correct to push a pallet jack or pull it. There’s no right or wrong answer to this question. When a manual pallet truck is empty, it doesn’t matter whether you pull or push it around. As long as you’re operating in an ergonomically safe and efficient manner, it depends on the direction you want the truck to go. It especially depends if you’re in a tight space and about to load or unload the jack.

Where pushing and pulling really matters depends on the weight of your load and the grade you’re operating in. Under flat circumstances, it’s always best to push a loaded pallet jack. Pushing is easier on the body and doesn’t exert the same tearing force that pulling does. You’ll find it considerably easier to push a loaded truck across a level floor, but that changes as soon as you’re faced with a ramp.

Again, it depends on the weight of your load and the degree of slope. You may find pulling safer and more efficient, especially when you need to use force to brake the load and keep it from free-wheeling. For significant slopes and heavy loads, the best practice is to work with a helper with one in front of the loaded jack and the other operating the handle.

Properly parking a manual pallet jack is another important safety tip. Empty pallet trucks are notorious tripping hazards. That includes being left with the forks extended out into aisle or leaving the handle outstretched. These simple tips about parking a pallet jack seriously improve warehouse safety:

Most of the previous safety tips for manual pallet trucks also apply to powered jacks. OSHA divides manual and electric-powered pallet jacks into two separate categories as powered units require more skill to operate. They also normally carry greater loads, which make powered units more dangerous. Therefore, OSHA makes it mandatory for all workers who operate powered pallet trucks to be trained and approved for safe use.

We’ll look at the specifics required for powered pallet jack training, but first, here are some tips specific to safely operating electric-powered trucks:

While proper training isn’t mandatory under OSHA legislation for manual pallet truck operators, the same isn’t true for workers using any form of pallet jack that’s powered by an artificial source. That includes electric powered pallet trucks as well as jacks with internal combustion engines. Practical training is highly recommended for all forms of pallet jack operating, but it’s a must for powered trucks.

OSHA provides a handy “Frequently Asked Questions” publication for powered industrial truck operator training. It covers exactly what employers and employees must know about electric truck operation as well as each party’s responsibilities under the law. These are the OSHA highlights:

Pallet truck safety is not a subject to be taken lightly. Neither is supplying pallet jacks. Cherry’s Material Handling has been providing material handling equipment like quality manual and electric pallet trucks to owners and operators across America for over three decades. Cherry’s Material Handling takes safety seriously and wants you to work safely, too.

Cherry’s Material Handling has knowledgeable sales staff who have experience with all forms of pallet jack equipment. We’ll be pleased to discuss our extensive line of manual and electric pallet trucks that range in capacity from light to heavy-duty machines.

Page updated on: February 18, 2021